Blog

Top Benefits of Direct Dyes in Fabric and Textile Industries?

The fabric and textile industries are increasingly turning to direct dyes for their vibrant colors and eco-friendly attributes. According to a report by Textile World, direct dyes account for approximately 30% of the global dye market. These dyes bond well with textiles, providing excellent colorfastness and ease of application. Expert Dr. Emily Hart, a leading authority in dye technology, notes, "The versatility of direct dyes cannot be overstated; they meet modern sustainability standards while delivering exceptional color quality."

The advantages of direct dyes extend beyond their aesthetic appeal. They offer a range of benefits such as reduced water usage during the dyeing process and simpler application methods, making them more cost-effective for manufacturers. However, challenges remain. For example, the long-term environmental impact of certain direct dyes can be complex. Manufacturers must navigate these issues carefully to align with sustainability goals.

As the industry evolves, the choice of dyes plays a crucial role in shaping consumer preferences. With a growing demand for eco-conscious products, direct dyes are positioned to lead the way. Yet, as Dr. Hart cautions, "The industry must continuously innovate to balance performance with environmental responsibility.

Overview of Direct Dyes in the Fabric and Textile Industries

Direct dyes are gaining popularity in the fabric and textile industries due to their vibrant colors and ease of use. They are water-soluble and can bond well with various types of fibers. This characteristic makes them suitable for diverse applications, including cotton and rayon fabrics. The application process is relatively simple, which appeals to manufacturers looking for efficiency.

The benefits extend beyond just color vibrancy. Direct dyes are versatile and can be applied in various methods, including pad and exhaust techniques. They significantly reduce processing times, which is crucial in today’s fast-paced market. However, there are challenges to consider, such as color fastness. Some fabrics may fade quickly with direct dyes, prompting a need for better dyeing techniques.

Environmental concerns also arise when using direct dyes. While they are often deemed safer compared to reactive dyes, wastewater from dyeing processes can still pose risks. Many in the industry are reflecting on sustainable practices to mitigate these impacts. The balance between vibrant, effective dyeing and environmental responsibility needs ongoing attention.

Advantages of Direct Dyes for Colorfastness and Vibrancy

Direct dyes are gaining popularity in the fabric and textile industries. Their benefits are significant, especially when it comes to colorfastness and vibrancy. These dyes bond well with cotton and other fibers, ensuring a bright and lasting color. When washed, garments dyed with direct dyes maintain their hue better than many other options.

It’s important to note that not all direct dyes perform equally. Some may fade over time or react poorly to certain detergents. Choosing the right dye is crucial. Always conduct a small test before dyeing large batches. This can save time and materials.

For optimal vibrancy, consider the dyeing conditions. Ensure proper temperature and pH levels during the process. Use hard water cautiously, as it can impact the dye’s effectiveness. Always store dyed fabrics in a cool, dark place to avoid unnecessary fading. Avoiding exposure to direct sunlight can help in maintaining that rich color.

Environmental Impact and Sustainability of Direct Dyes

Direct dyes are gaining attention in the fabric and textile industries for their environmental sustainability. Unlike some synthetic dyes, direct dyes can minimize water consumption during dyeing. A report from the International Textile and Apparel Association states that direct dyeing processes often use 30% less water compared to traditional methods. This not only conserves water but also reduces the energy needed for heating during dyeing.

Yet, challenges remain. Some direct dyes may not be as lightfast or washfast as reactive dyes. This can lead to color fading after several washes. Additionally, the effluent from the dyeing process must be treated properly to prevent pollution. A study by the World Bank highlighted that 17-20% of industrial water pollution comes from textile dyeing.

Tips: Consider using exhaust dyeing techniques to reduce water waste. Always test dye color fastness on sample fabrics to ensure satisfaction. Educating textile workers about sustainable practices can further enhance environmental benefits. As the industry shifts toward sustainability, continuous improvement is essential.

Top Benefits of Direct Dyes in Fabric and Textile Industries

| Benefit | Description | Environmental Impact | Sustainability |

|---|---|---|---|

| Vivid Colors | Direct dyes offer vibrant and intense colors, enhancing fabric aesthetic appeal. | Lower waste due to fewer dyeing cycles needed for color intensity. | Can be produced from sustainable natural sources. |

| Ease of Application | Direct dyes can be easily applied in one step, minimizing processing time. | Reduced energy consumption due to shorter processing times. | Optimizes resource use and boosts efficiency. |

| Water Usage | Requires less water compared to other dyeing methods like reactive dyes. | Conserves water resources, vital in water-scarce areas. | Supports responsible water management practices. |

| Low Toxicity | Many direct dyes are less toxic compared to azo dyes and other synthetic dyes. | Safer for workers and reduces environmental hazards. | Promotes better safety standards in textile manufacturing. |

| Biodegradable Options | Certain direct dyes are derived from natural resources, making them biodegradable. | Reduces long-term environmental impact from fabric waste. | Aligns with circular economy principles in textiles. |

Cost-Effectiveness of Direct Dyes in Textile Production

Direct dyes have become a popular choice in the textile industry due to their cost-effectiveness. They are often more affordable compared to other dye types, which reduces overall production costs. This advantage makes them attractive for manufacturers looking to optimize their budgets. Producers can offer lower prices to customers, enhancing market competitiveness.

Using direct dyes can also streamline the dyeing process. This type of dye often requires less water and energy during application. For manufacturers aiming to improve sustainability, this feature aligns well with eco-friendly goals. However, the performance of direct dyes can vary. Some may have lower lightfastness. Keeping this inconsistency in mind is essential for quality control.

**Tips:** Always test dye samples before large-scale production. This helps in identifying issues early on. Monitor the environment in the dyeing process. Variations in temperature and pH can impact results. Lastly, consider customer feedback. This input can guide future dyeing choices and help refine techniques.

Top Benefits of Direct Dyes in Fabric and Textile Industries

This chart illustrates the top benefits of using direct dyes in the fabric and textile industries, highlighting their cost-effectiveness and other vital factors that enhance textile production.

Applications and Versatility of Direct Dyes in Various Fabrics

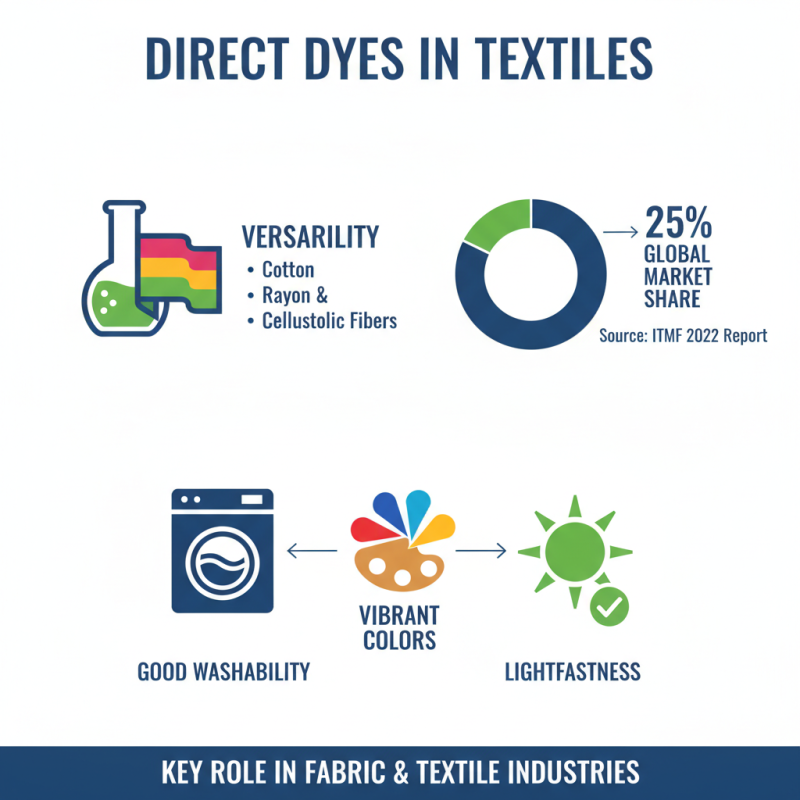

Direct dyes play a crucial role in the fabric and textile industries due to their versatility. They are used extensively on cotton, rayon, and other cellulosic fibers. According to a 2022 report by the International Textile Manufacturers Federation, direct dyes account for around 25% of the global dye market. Their ability to provide vibrant colors while offering good wash and light fastness makes them popular among manufacturers.

In applications, direct dyes excel in various textile segments. They are ideal for dyeing woven and knitted fabrics, achieving a uniform and rich color. The ease of application, typically through simple dyeing processes, allows for faster production cycles. Notably, the range of shades available can meet diverse consumer demands. However, one should consider the environmental impact. Some direct dyes can raise concerns regarding toxicity and ecological safety.

Tip: Always conduct a color fastness test before bulk production. This can help identify any potential issues early. Remember, proper washing and finishing processes are vital. Quality control during dyeing can minimize defects and ensure greater customer satisfaction. Balancing vibrant designs with responsible dyeing practices is key.

Related Posts

-

Top 10 Specialty Chemicals Driving Innovations in Various Industries

-

How to Choose the Best Water Soluble Dye for Your Craft Projects

-

What is Solvent Pigment and How Does it Impact Your Art Projects

-

Top Trends Shaping the US Chemical Industry in 2023

-

Understanding Solvent Pigments in 2025 Top Applications and Innovations

-

How to Choose the Right Chemical Raw Materials for Your Projects