Blog

How to Choose the Right Chemical Producers for Your Business Needs?

Selecting the right chemical producers is crucial for any business. According to industry expert Dr. Emily Carter, "The quality of your chemical suppliers can make or break your operations." Businesses rely heavily on chemicals for various applications. Choosing the wrong supplier can lead to costly setbacks.

Identifying the right partners in the chemical industry requires careful evaluation. Companies should assess their specific needs. Are you looking for specialty chemicals or bulk production? The nature of your requirements influences your choice. Additionally, consider the reliability and track record of potential suppliers.

It's essential to weigh factors beyond just price. Think about quality control and delivery times. Some chemical producers may offer lower prices but risk poor quality. This can jeopardize your entire production line. Reflecting on these challenges is indispensable for making informed decisions.

Understanding Your Business Requirements for Chemical Production

Understanding your business requirements for chemical production is essential. The needs vary widely between industries. A study found that 75% of manufacturers prioritize flexibility in production capacity (source: Chemical Industry Report 2022). Knowing your specific needs can guide your choice of a chemical producer.

Secondly, consider the quality standards you require. Different applications have distinct specifications. For instance, pharmaceuticals demand stricter regulations than agricultural chemicals. About 20% of companies reported issues with product quality due to misalignment with producers (source: Industry Quality Survey 2023). Reflection on your quality expectations is crucial.

Moreover, pricing and delivery times play a vital role in the decision-making process. Data shows that 60% of businesses reported facing delays due to unreliable suppliers (source: Supply Chain Efficiency Study 2023). A producer that fits your budget may not always meet your timeline. Exploring this balance is essential for sustained production.

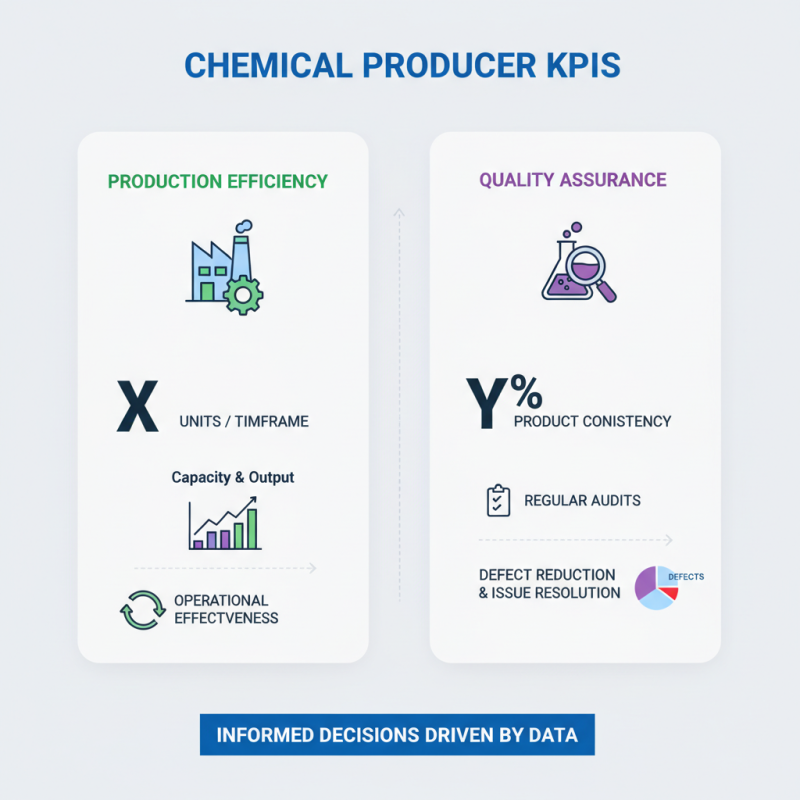

Identifying Key Performance Indicators for Chemical Producers

Identifying key performance indicators (KPIs) for chemical producers is crucial for making informed decisions. Start by considering production efficiency. How many units can they produce in a given time frame? This number reflects their capacity and operational effectiveness. Next, assess quality assurance metrics. Consistency in product specifications is vital for business needs. Regular audits can reveal patterns in defects or issues.

Another important KPI is delivery reliability. Measure how often producers meet their deadlines. Delays can disrupt your supply chain and impact your business. It's worth tracking the average time taken for shipments. Additionally, consider customer service responsiveness. How quickly do they address queries or concerns? A slow response can strain your relationship.

Financial stability is also a factor. Look at their pricing models and payment terms. Are they competitive? Are there hidden costs? A solid financial background indicates reliability. Reflect on areas where these producers may fall short. Are their communication processes unclear? Or do they struggle with scalability? Understanding these aspects can lead to better partnerships and improved outcomes.

Evaluating Production Capacities and Supply Chain Efficiency

When selecting a chemical producer, assessing their production capacities is vital. A manufacturer with robust production capabilities can handle large orders efficiently. Ensure they have the right technology and expertise. Check their equipment and facilities. Are they up-to-date and well-maintained? This can greatly impact quality and reliability.

Supply chain efficiency is equally crucial. A producer with a smooth supply chain can deliver products on time. Look for their logistics arrangements. Do they have multiple transport options? This flexibility can minimize delays. Investigate their sourcing strategies as well. A strong network of suppliers can enhance resilience.

Remember, no producer is perfect. Some may promise quicker turnaround times but struggle with quality. Others might excel in product quality but lack flexibility. It's essential to weigh these factors carefully. The right balance between capacity and efficiency can drive your business forward. Look beyond the promises. Evaluate actual performance metrics to make a confident choice.

Assessing Regulatory Compliance and Environmental Standards

Choosing chemical producers is a significant decision. Assessing regulatory compliance is crucial. Each region has its own standards. Companies must adhere to these rules. Always verify the certifications they hold. This step helps ensure the safety of your products.

Environmental standards deserve equal attention. Look for producers committed to sustainable practices. They should minimize waste and emissions. Check for eco-friendly certifications. Investigate their manufacturing processes. Not all companies are transparent. Some may overlook important details.

Reflect on your own values too. How important is sustainability to your business? Are you willing to compromise quality for cheaper prices? These questions can guide your choices. Finding the right balance is not easy. It requires careful thought and consideration. Be prepared to dive deeper into potential partners.

Analyzing Cost Structures and Pricing Models in the Chemical Industry

When selecting chemical producers, understanding their cost structures is crucial. Different producers use various pricing models, and these can significantly impact your bottom line. Some companies may offer bulk discounts, while others might have fixed pricing. Analyzing these structures helps identify which model fits your budget. Consider asking potential suppliers for detailed breakdowns of their pricing. This can reveal hidden costs.

Additionally, it’s important to look at pricing fluctuations. Prices in the chemical industry can vary based on supply chain issues or raw material costs. Producers who adjust prices frequently may not offer stability. Reflect on how these changes can affect your planning. Assess whether you are prepared for potential ups and downs. A good partnership involves transparency and reliability in pricing.

You should also evaluate the total cost of ownership. This includes not just the price per unit, but also aspects like delivery fees, storage costs, and wastage. Some producers may seem cheaper initially, but hidden charges can add up. Engage in discussions about these factors with potential partners. It is vital to ensure a complete understanding of what you are committing to.

Related Posts

-

How to Choose the Right Chemical Raw Materials for Your Projects

-

Top 10 Specialty Chemicals Driving Innovations in Various Industries

-

The Best 10 Solvent Soluble Dyes for Your Projects?

-

Top 10 Pigment Color Trends You Should Know About?

-

Top Benefits of Direct Dyes in Fabric and Textile Industries?

-

How to Choose the Best Water Soluble Dye for Your Craft Projects