Blog

How to Choose the Right Chemical Raw Materials for Your Projects

Choosing the right chemical raw materials is crucial for project success. Expert Dr. Emily Chen, a leading figure in the chemical industry, emphasizes, "Selecting appropriate materials can make or break your project." This highlights the importance of thoughtful decision-making.

When it comes to chemical raw materials, factors like purity, source, and cost should guide your choices. Engaging with suppliers can sometimes feel overwhelming. Not all suppliers provide the same quality. Understanding your project’s unique requirements is vital. It is essential to consider how the specific chemical raw materials will interact with other components.

Mistakes in material selection can happen easily. Projects might face delays or unexpected costs. A single wrong decision about chemical raw materials could lead to serious consequences. Therefore, thorough research and consultation with experts can help avoid these pitfalls. Always re-evaluate your options and remain flexible. This approach ensures that your project progresses smoothly and successfully.

Understanding the Importance of Selecting Quality Chemical Raw Materials

Choosing quality chemical raw materials is crucial for any project. The right materials can enhance product performance and ensure safety. Poor quality chemicals can lead to failures and unexpected reactions. It’s essential to understand the specific requirements of your project before sourcing materials.

Pay attention to purity levels and specifications. Quality raw materials should align with your project’s goals. This alignment impacts not just the end product but also the production process. Suppliers should provide detailed information about their chemicals. Engage in conversations to clarify doubts and confirm quality.

Consider the sourcing process as well. It may seem straightforward, but choosing the wrong supplier can lead to serious issues. Research their reputation and reliability. Feedback from previous clients can provide insight into their quality standards. Reflect on your own experience with suppliers, and seek continuous improvement.

Identifying Key Characteristics of Suitable Chemical Raw Materials

Choosing the right chemical raw materials is critical. The process begins with understanding the key characteristics needed for your project. These characteristics can include purity, reactivity, and stability. For instance, high purity is essential for applications in pharmaceuticals and food production. Any contaminants can alter the final product significantly.

Reactivity is another important factor. Some chemicals react easily with air or moisture. It’s essential to consider how these interactions may affect your project. Stability also plays a crucial role, especially for materials stored over time. An unstable chemical can degrade, resulting in wasted materials and time. Thoroughly analyzing these aspects will help in making informed decisions.

However, the selection process can be challenging. You might discover discrepancies between the intended use and the material's actual performance. It's normal to revisit your choices based on testing results. Reflecting on your selection criteria can lead to better future decisions. Ultimately, finding the right balance of characteristics is key.

Comparison of Key Characteristics of Chemical Raw Materials

Evaluating Supplier Credentials and Industry Standards for Raw Materials

When selecting chemical raw materials, evaluating supplier credentials is crucial. A survey by the American Chemical Society shows that 70% of businesses faced quality issues due to poor supplier vetting. Reliable suppliers often provide certifications indicating compliance with industry standards. However, the presence of these certifications alone does not guarantee quality.

Some suppliers may display certifications without adequate background verification. According to a recent industry report, nearly 30% of companies mentioned they do not perform thorough checks on supplier claims. This can lead to sourcing subpar materials that compromise project integrity. Engaging with suppliers who have a transparent history and track record is vital.

Understanding industry standards is equally important. The ISO 9001 certification ensures consistent quality management. Yet, not all suppliers adhere strictly to these guidelines. A report from the Chemical Manufacturers Association noted that 25% of suppliers failed to meet these standards consistently. Developing a checklist for evaluating suppliers based on industry benchmarks can mitigate risks. However, many overlook this step, risking flaws in their projects.

How to Choose the Right Chemical Raw Materials for Your Projects

| Raw Material | Supplier Rating | Industry Standards Compliance | Lead Time (weeks) | Price per Unit ($) |

|---|---|---|---|---|

| Acetic Acid | 4.5/5 | ISO 9001 | 2 | 1.20 |

| Sodium Chloride | 4.0/5 | FSSC 22000 | 1 | 0.50 |

| Benzene | 4.2/5 | REACH | 3 | 2.50 |

| Sulfuric Acid | 4.8/5 | OSHA | 4 | 3.00 |

| Ethanol | 4.3/5 | ASTM D4806 | 2 | 1.80 |

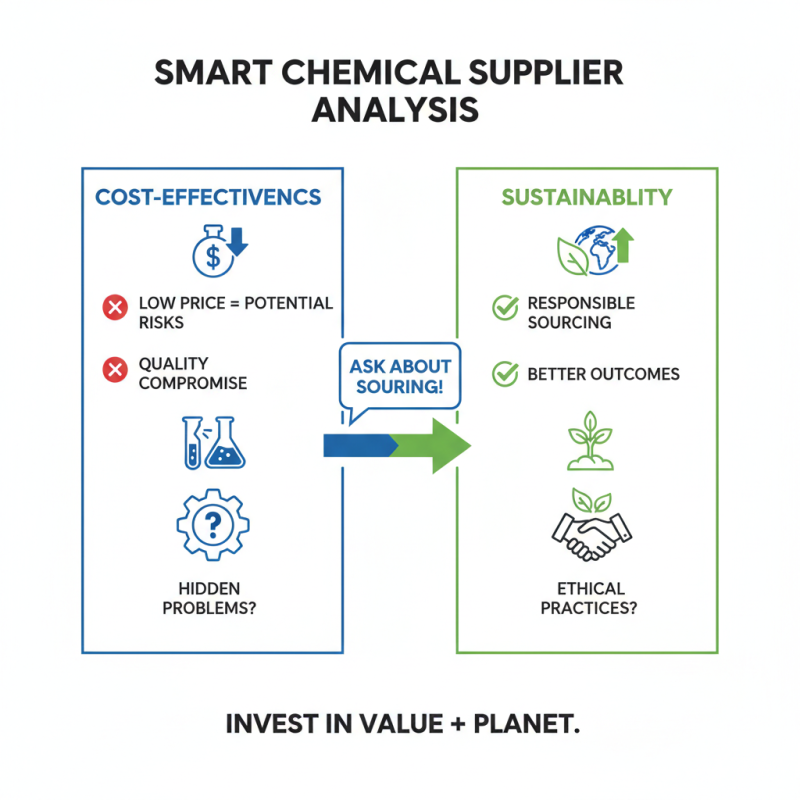

Analyzing Cost-Effectiveness and Sustainability of Chemical Suppliers

When analyzing chemical suppliers, cost-effectiveness and sustainability are crucial. A low price might be tempting, yet it can signal hidden problems. Quality can suffer in cheaper materials, affecting project outcomes. It’s essential to ask suppliers about their sourcing practices. Responsible sourcing often costs more, but it leads to better results.

Sustainability is another key factor. Check if a supplier adopts eco-friendly practices. This includes using renewable energy and reducing waste. Some suppliers might claim sustainability but lack certifications. Transparency is vital. Verify claims with third-party organizations. Ethical practices can boost your project's reputation and long-term savings.

Choosing the right supplier goes beyond price. Consider the materials' lifecycle and environmental impact. Sometimes, higher upfront costs can lead to lower overall expenses. Reflect on your project’s values and goals, as they should align with your supplier choices. This will not only ensure compliance but also contribute to a responsible and thriving future.

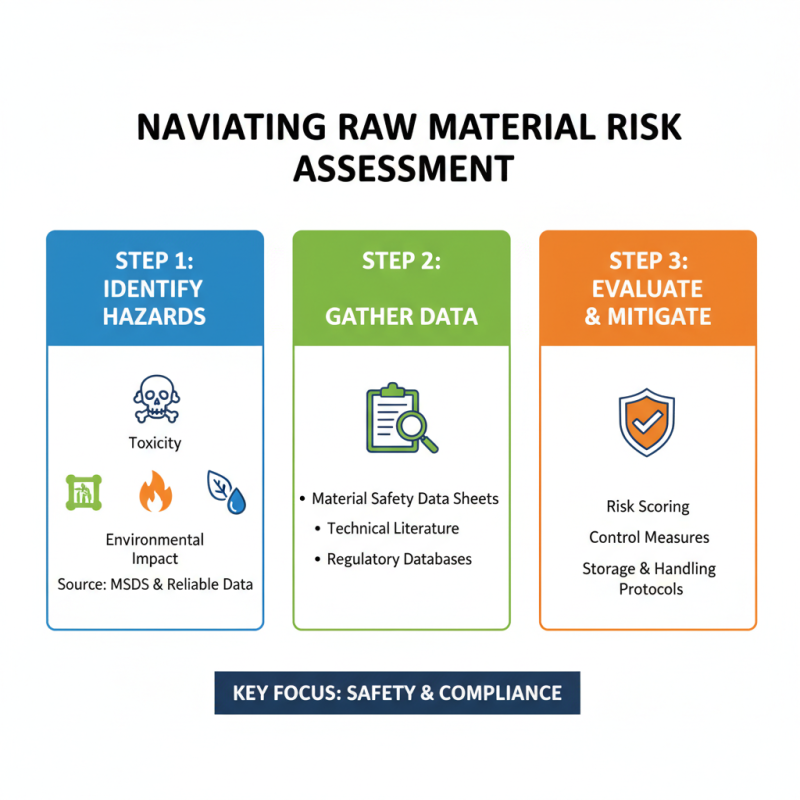

Conducting Risk Assessments for Chemical Raw Material Selection

Choosing the right chemical raw materials is a complex task. Conducting risk assessments is a crucial step in this process. Begin by identifying potential hazards associated with the materials you are considering. This can include toxicity, flammability, or environmental impact. Collect data from material safety data sheets (MSDS) and reliable sources to help you understand these risks.

Next, evaluate the likelihood of incidents occurring. Think about scenarios where exposure might happen. Will there be leaks during transportation? What about spills during mixing? Look at historical data if available. That can provide insights into past issues. Don’t overlook the importance of context. The same material can pose different risks based on location and usage.

Finally, involve your team in discussions around these assessments. This collaboration can bring new perspectives and identify overlooked risks. Document everything meticulously to ensure transparency in your decision-making. It is essential to be critical and reflective about the outcomes of your assessments. Remember, this process is iterative and should evolve with ongoing projects.

Related Posts

-

Top 10 Specialty Chemicals Driving Innovations in Various Industries

-

What is Solvent Pigment and How Does it Impact Your Art Projects

-

How to Choose the Best Water Soluble Dye for Your Craft Projects

-

Top Trends Shaping the US Chemical Industry in 2023

-

Understanding Solvent Pigments in 2025 Top Applications and Innovations